What goes into making a wine special?

Great Grapes

All good wines begin with great grapes. Our wines are made from 100% pure and natural Vitis vinifera grapes. The grapes we use are harvested from choice vineyards all over the world – Italy, Spain, Chile and more.

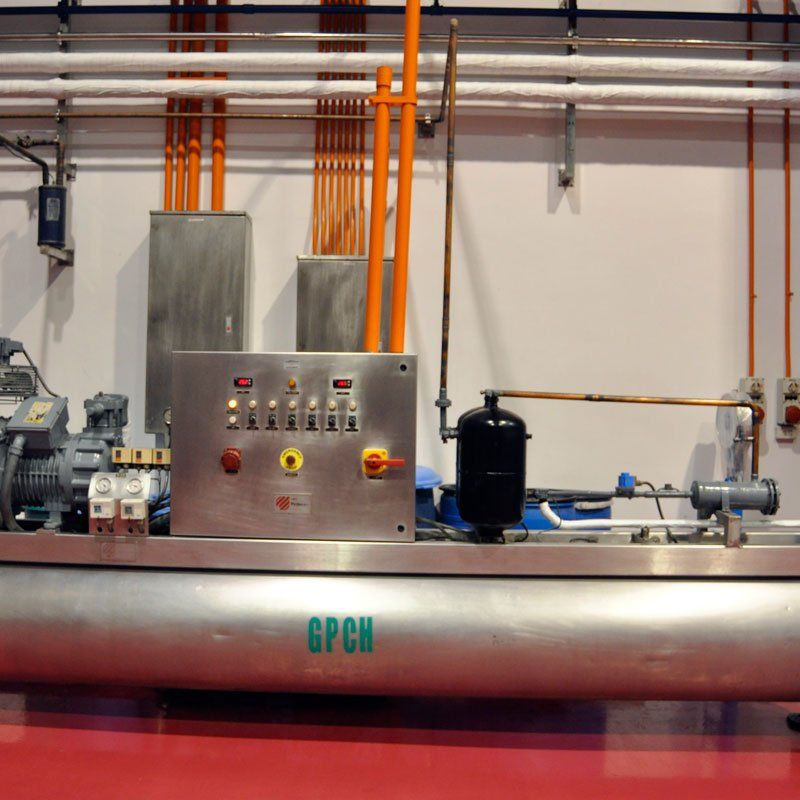

Modern Winery

We make our wine at our new winery in Carmelray Industrial Park I, Canlubang, Calamba, Laguna, province south of Manila. It’s a state-of-the art facility equipped with the latest Italian winemaking technology and also the biggest in the country and one out of only 3 in Asia. And that is something we’re really proud of.

A Veteran Winemaker

Franco Nosenzo is our winemaker. He’s been with us since the very beginning. Through the years, he’s been travelling back and forth from his home in Italy to the Philippines, to make our wines and whenever we need him. Franco brings to our wines all that is great about the Italian way of making wine.

The way we make our wine:

Fermentation

Yeast is what gets the fermentation process going. Yeast interacts with the sugars from the grape juice and converts sugar to alcohol and carbon dioxide. With the passage of time, more and more of the sugars turn into alcohol. If all of the sugars have been converted to alcohol, the wine is deemed "dry".

At Novellino, we don't make our wine dry. We keep a close eye on the alcohol level, because we want to retain some of the natural sugars present in the grape juice to make our wine sweet. Depending on how sweet we want our wine to be, we stop or “arrest” the fermentation at a specific point. The sooner fermentation is stopped, the sweeter the taste of the wine. And, sweet is what we want most of the time.

All this goes on in our three double-jacketed stainless steel, temperature-controlled fermentation tanks imported from Italy.

Centrifugation

Once we achieve our optimal level of sugar and alcohol from the fermentation process, we pass the wine through centrifugation. Remember, our wine is partially fermented, so in order to keep the wine from fermenting further, we need to remove the yeasts and lees- this process does just that (Lees are the natural residue or the byproducts of fermentation).

At our winery, we have the latest in centrifuge technology. Imported from Sweden, our Alfa Laval centrifuge machine is among the best in the world. Not only that, we are proudly the first and one of the the only in Asia to have this kind of equipment for wine making.

Clarification, Filtration, Adjustment

There’s still a lot more work to be done. Like most modern wineries, we inject natural clarifying agents to help refine our wine (such as egg whites). After the clarifying agents do their job, we remove them using natural diatomaceous earth-more commonly known as a "green filter".

After this filtration, every employee in the factory tastes the wine for the first time. We make sure that our wine meets our standards and specifications and, if necessary, make adjustments.

Then we have yet another round of filtration, just to make sure our wine is clear of all unwanted debris.

Our three-stage micro-filtration process makes sure that we get rid of all debris as small as .45 micron—that’s about 1/1000 the diameter of a single human hair and much, much less than the size of bacteria which measure around 5 microns. Nothing passes but pure liquid fresh wine!

Chilling

Once our wine is all clear, we chill. Literally. Our wine is cooled to a temperature of 0 to -2 degree Celsius so we can reintroduce CO2 to our wine.

CO2 or "carbon dioxide" is what makes our wine effervescent and delightfully refreshing. If you recall, CO2 is a bi-product of fermentation, however it escapes when the wine leaves the fermentation tank so we reintroduce it back to the wine.

Bottling

Before the bottles meet the wine, they are cleaned and rinsed with reverse-osmosis purified water. Once clean, they are filled with fresh wine. Bottles are then capped, corked, dried, sealed, packed into boxes, and soon, on the way to a store near you!

Fermentation

Yeast is what gets the fermentation process going. Yeast interacts with the sugars from the grape juice and converts sugar to alcohol and carbon dioxide. With the passage of time, more and more of the sugars turn into alcohol. If all of the sugars have been converted to alcohol, the wine is deemed "dry".

At Novellino, we don't make our wine dry. We keep a close eye on the alcohol level, because we want to retain some of the natural sugars present in the grape juice to make our wine sweet. Depending on how sweet we want our wine to be, we stop or “arrest” the fermentation at a specific point. The sooner fermentation is stopped, the sweeter the taste of the wine. And, sweet is what we want most of the time.

All this goes on in our three double-jacketed stainless steel, temperature-controlled fermentation tanks imported from Italy.

Centrifugation

Once we achieve our optimal level of sugar and alcohol from the fermentation process, we pass the wine through centrifugation. Remember, our wine is partially fermented, so in order to keep the wine from fermenting further, we need to remove the yeasts and lees- this process does just that (Lees are the natural residue or the byproducts of fermentation).

At our winery, we have the latest in centrifuge technology. Imported from Sweden, our Alfa Laval centrifuge machine is among the best in the world. Not only that, we are proudly the first and one of the the only in Asia to have this kind of equipment for wine making.

Clarification, Filtration, Adjustment

There’s still a lot more work to be done. Like most modern wineries, we inject natural clarifying agents to help refine our wine (such as egg whites). After the clarifying agents do their job, we remove them using natural diatomaceous earth-more commonly known as a "green filter".

After this filtration, every employee in the factory tastes the wine for the first time. We make sure that our wine meets our standards and specifications and, if necessary, make adjustments.

Then we have yet another round of filtration, just to make sure our wine is clear of all unwanted debris.

Our three-stage micro-filtration process makes sure that we get rid of all debris as small as .45 micron—that’s about 1/1000 the diameter of a single human hair and much, much less than the size of bacteria which measure around 5 microns. Nothing passes but pure liquid fresh wine!

Chilling

Once our wine is all clear, we chill. Literally. Our wine is cooled to a temperature of 0 to -2 degree Celsius so we can reintroduce CO2 to our wine.

CO2 or "carbon dioxide" is what makes our wine effervescent and delightfully refreshing. If you recall, CO2 is a bi-product of fermentation, however it escapes when the wine leaves the fermentation tank so we reintroduce it back to the wine.

Bottling

Before the bottles meet the wine, they are cleaned and rinsed with reverse-osmosis purified water. Once clean, they are filled with fresh wine. Bottles are then capped, corked, dried, sealed, packed into boxes, and soon, on the way to a store near you!

Philippines

Calabria Company Limited - Manila Branch Office

Makati City, Metro Manila

Email: info@novellinowines.com

Tel. No.: (63) 2 5310 2063

Fax: (63) 49 508 2774

United Arab Emirates

Truebell Marketing & Trading LLC - DubaiDubai Investment Park – II, DubaiTel No: (971) 4 885 6968Fax: (971) 4 885 6977

Vietnam

World Wine Co., Ltd.

Ho Chi Minh City, Vietnam

Email: thienhuong@passion.vn

Tel. No: (84) 8 3970 7667

Fax: (84) 8 865 9482

All Rights Reserved | Novellino Wines